2020, DAERA (NI)

CE-Hub Digital Series: Extending Product Lifespans

CE-Hub, 2023

Lifespans and the circular economy

As part of the UKRI NICER programme to deliver research, innovation, and the evidence base needed to move towards a more resilient UK circular economy, this series of articles examines the potential benefits of lifespan extension across different product groups and explores the technological, economic, social and policy changes which can help realise these benefits here in the UK.

In a 2022 survey by YoungPlanet, a majority of UK adults reported being unfamiliar with the term ‘circular economy’. At the same time, a 2018 survey by the Green Alliance found most respondents were frustrated with the short lifespans of products.

A key aim of the circular economy is to enable materials, products and components to circulate in the economy at their highest value for the longest time. So, while people may not be familiar with the term ‘circular economy’, they do understand that many products break or become obsolete well before their potential lifespan. Product life extension is therefore an effective way to communicate and directly engage people with circular economy.

The length of time it takes materials and products entering the UK economy to exit it as waste is a key determinant of environmental impact and indicator of (un)sustainable consumption (Cooper, 2005). Alongside the substitution of primary for secondary materials, reduced material flows and higher resource productivity, the circular economy has been defined in terms of longer material, component and product lifespans.

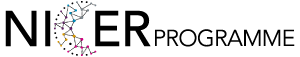

Figure 1.

Circular economy levers to boost resource productivity and carbon benefits

(M. Zils, 2023)

Figure 1 illustrates the importance of product life extension within a circular economy. It increases the overall utility of a product meaning more service or performance from the embodied materials and emissions within the product. This is a key to overall resource productivity of the economy. Lifespan extension can’t do away entirely with waste, but it delays its generation and can offset demand for virgin materials. Lifespan extension also has the potential to bring a further range of circular benefits when coupled with products, materials and components being returned back into the economy. Whilst this is currently possible with existing products, increased circulation at higher value will require changes in product design, business models, reverse logistics and enablers such as policy.

The benefits of lifespan extension

Environmental case

Multiple studies have pointed to the potential environmental benefits of product lifespan extension (Hertwick et al. 2019; Norman et al. 2021). In assessing pathways for meeting the 6th carbon budget, the UK Climate Change Committee estimate that longer-lived products could yield 2 MtCO2e of emissions savings per year by 2035, equivalent to taking approximately 1 million cars off the road (CCC, 2020). An earlier 2011 report by ERM also found additional lifecycle environmental benefits through extending the life of 9 commonly used products in the UK from avoiding waste and new production.

At the same time, efficiency improvements or technological shifts towards less environmentally costly inputs can in some cases make it no longer desirable to continue to extend the lifespan of an existing product versus replacing it (González et al. 2017). Resultantly, lifespans are not a reliable indicator of impact by themselves, and the full life-cycle or value chain of a product needs to be assessed (Hummen and Desing, 2021).

For instance, UN Environment (2017) found that the energy efficiency savings from moving from one laptop generation to the next was around 10%, and when compared with upstream environmental impacts, the optimal replacement moment for laptops was therefore around 7 years. The balance of impacts across production and use phases depends on a range of factors including product resource demand, use frequency and the environmental-intensity of used resources e.g. electricity.

Economic and social case

A predominantly linear economy based on ‘take, make and throw’ has powered growth and jobs for decades in the UK, with businesses generating revenue through high product turnover and relatively little recovery of resources. There are a growing number of examples of businesses supporting product life extension for economic and social benefit. IFixit is a well known example offering tools, information and video tutoring on how to repair many everyday electronic products while also rating their repairability to inform consumers at the point of purchase.

Longer-lasting products have the potential to save consumers money through avoiding replacement, particularly relevant during the current cost of living crisis. With the cost of waste management to UK government £12.4 billion in 2020 and largely falling on local authorities (ONS, 2022), the scope to reduce these through diverting waste from landfill, for instance, can help improve public finances.

Researchers on the NICER programme are working on a range of product life extension projects, including extending the life of valuable aluminium and steel components, designing modular clothing products combined with services to increase repairability, and CE interventions to maintain the performance of rare earth permanent magnets within electrification technologies such as wind turbines and electric vehicle motors across multiple life cycles. Such innovations can be not only profitable and in some cases more profitable than the original sale, but also necessary to maintain competitiveness (European Commission, 2016). Oakdene Hollins (2022) estimate the total annual revenues associated with value retention processes such as repair and remanufacturing is over $75 billion in the UK, with significant scope to grow.

What can the data tell us?

Several studies have pointed to shortening product lifespans. For example, a 2013 study in the Netherlands found that between 2000 and 2006, average lifespans in 14 out of 15 reviewed electronic product groups had fallen (Wang et al. 2013). In the UK, it can be difficult to know if similar dynamics are at play as information on the age and lifespans of products and assets is not widely published. This said, a range of web articles, research studies and datasets can be pieced together to give something of a picture (for more information on curating data sets for circular economy measurement and monitoring, see our guide here).

Our electronics

The title for the oldest working electronics in the UK is contended, getting periodic coverage in the media and including the reportedly oldest:

Iron – 80 years old; Fridge – over 80 years; Light bulb – over 130 years; Washing machine – over 60 years; Computer – over 70 years; Stove – over 67 years; and Mobile phone – over 20 years.

Figure 2.

Sydney and Rachel Saunders’ washing machine, reportedly the oldest in Devon (Credit: Devon Live)

Although difficult to confirm these claims or know how common it is for those ages to be reached, they tell us something about what is possible when it comes to product longevity. We can say with a fair degree of certainty nevertheless, that such ages are unlikely to be representative of the vintage of most electronic products in use today.

The Open Repair Alliance’s citizen science data on products brought to repair cafes captures information on the year of product manufacture and success of a repair attempt for cafe visits (Figure 3). While adding to our understanding, it can also be difficult to know how representative these figures are as products brought to repair cafes may have owners more inclined to preventative maintenance than the general population.

Figure 3. Age of products at time of repair attempt (Open Repair Alliance, 2021)

Other sources can help build up a further picture such as the average length of guarantees reported in manufacturer and retail documentation (e.g. those collated by the firm Magnet). From studies commissioned by the Government such as the 2021 ‘UK Energy-related Products Policy Study’, estimates for average, upper and lower values across a range of product groups can also be found.

Our buildings

Data on the length of time buildings remain in the UK productive stock is a key input into calculations of the UK’s national balance sheet made by the Office for National Statistics (ONS), though relatively little is known about what these actually look like in practice (Rincon-Aznar, Riley and Young, 2017). Estimates drawn on for this purpose include a median lifespan of 59 years for dwellings and 75 years for buildings more generally. These assumptions derive from a variety of sources including figures compiled by other National Statistical Institutes and are updated on a periodic basis.

The UK Valuation Office Agency (VOA) publish statistics on the stock of domestic property in England and Wales, including their build period by region (Figure 4). These indicate that more than a fifth of taxed houses in England and Wales were built before 1919 while half were built before 1964. This spread also differs by region, with London having the highest concentration of older properties.

Figure 4. Distribution of the age of dwellings in the UK (VOA, 2022)

As with electronics, buildings are made up of a whole range of components, many of which will be replaced during the lifetime of a property or even in some cases outlive it. Maintenance of components is an important part of realising the expected service life of buildings. Repair and maintenance make up a significant share of construction industry output – a sector that comprises a 6% share of national value added and employs around 1.5 million people (ONS, 2022; ONS, 2022).

Figure 5.

Bromley Hall, London built around 1485 and reportedly the oldest brick building in the capital. (Credit: O. Lysaght)

Our vehicles

The way we travel in the UK has changed significantly over the last several hundred years (Government Office for Science, 2018; 2019). With the expansion of the railway, a journey of five days between London to Manchester in 1750 had shrunk to just four hours by 1880. The use of personal motor vehicles has grown as a means of transport since the 1950s, and with it, distances travelled. As the chart shows, the COVID pandemic has also had a significant impact (Figure 6).

Figure 6. Passenger transport by mode,1952-2021, billion passenger km (DfT, 2022)

Data on the age of vehicles in the UK is collected by the DVLA and published by the Department for Transport (DfT). This indicates the most common age for vehicles is 6 years old, the average age of registered vehicles is around 10 years and the vast majority of vehicles are less than 25 years old (Figure 7). The typical age of cars at the point they are scrapped in the UK is estimated to be around 14 years at present (Oguchi and Fuse, 2015; Held et al. 2021).

Figure 7. Distribution of the age of cars in the UK (DfT, 2022)

Extending lifespans

Time across the linear value chain

Goods can be separated into three broad categories based on the length of time they remain in the economy:

- Non-durables – sometimes referred to as fast-moving consumer goods, which enter and leave the economy relatively swiftly due to being perishable or consumed quickly;

- Semi-durables such as textiles; and

- Durable goods, which typically have an expected lifespan of over three years.

‘Global residence time’ can be used to refer to the total period a material resides in the global economy between resource extraction and disposal. With increasingly globalised supply chains, and the UK being a net importer of goods, many of these stages may not occur within the UK, or only partially. The global residence time can therefore be further subdivided into a ‘domestic residence time’ i.e. the period a material resides in the UK economy.

The word ‘lifespan’ refers to the interval of time an object exists in a particular form or context for. In an entirely linear economy, material lifespans are as long as the first use of the components and products in which they are used and production and disposal time. Most sources of data on the age and lifespan of goods focus on time in the ‘usage phase’. This can be further subdivided into the time in which a good is actually in use i.e. its service lifespan and when out of use.

These definitions refer to actual or realised lifepans and can be distinguished from:

-

- Designed or technical lifespans – the period that manufacturers intend goods to remain functional for;

-

- Economic lifespan – the period before which a product is no longer the least expensive way of performing its function; and

-

- Desired lifespan – the time that users want products and their components to last (UCL). For instance, the highest number of respondents to the big repair project survey of average lifespan expectancy reported 10 years for large and small electrical appliances (Big Repair Project, 2022).

Lifespan extension

The length of time it takes materials entering the UK economy to exit it as either waste or exports also varies levels with the level recirculation in the economy for products, constituent components and materials across end-uses.

‘First use extension’ involves an initial user keeping a product in its original form for as long as possible while use-phase intensification involves extending service lifespan and can also be measured in terms of the number of product uses. Lifespan extension needn’t stop at this, however. The length of time it takes materials entering the UK economy to exit it as either waste or exports also varies levels with the level recirculation in the economy for products, constituent components and materials across end-uses. Repair, reuse and refurbishment can add a second or third use to a product.

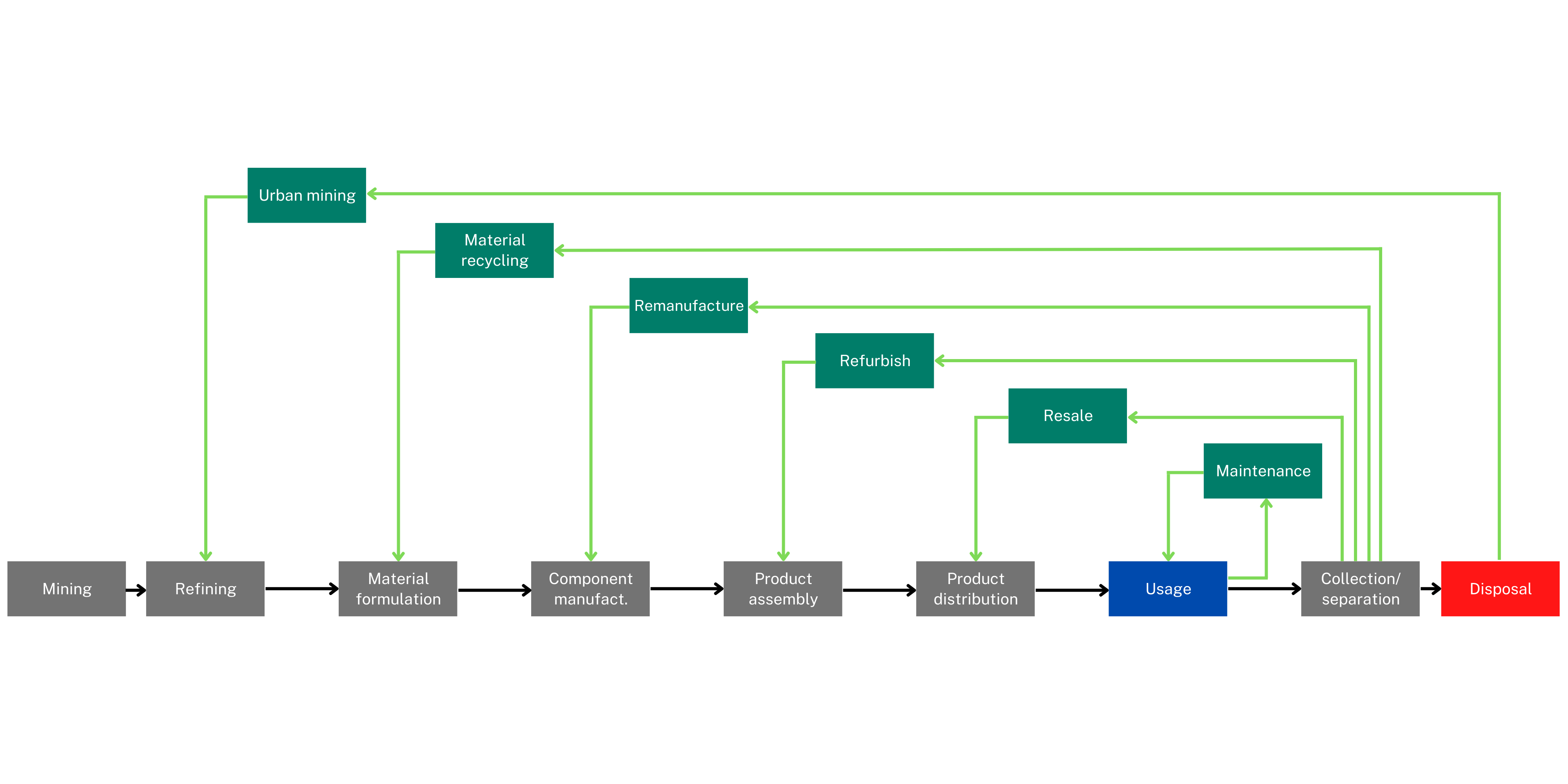

Other ‘reverse loops’ such as recycling involves returning a product or component back into its material elements and reformulating components from there. These cascading uses can see materials and components become feedstocks for other sectors, thereby extending their residence time further (Figure 8).

Figure 8.

The CE-Hub value chain taxonomy of circular value-retention activities (M. Zils, 2023)

The lifespan extension of materials, components and products via these circular economy strategies can be additive. For instance, a product might be kept in first use for longer, followed by being resold and then recycled. Refurbishment, remanufacture or recycling requires an injection of resources nevertheless which must be considered against the purchase of new to account for full lifecycle impacts (European Commission, 2015).

Strategies

A number of changes and strategies can help extend the lifespan of goods in the UK economy. This series on lifespan extension will explore these to help leverage the potential benefits of longer product lifespans here in the UK.

One key challenge is that many products have not been designed from the outset in a way that is durable or can support repeat uses. The most effective types of changes in design may need to vary between non-durable, semi-durable and durable products (SOENECS, 2021), but can involve increasing the durability such as of critical components, making products easier to disassemble and repair more accessible through being possible using standardised repair tools (Cole et al. 2016). In some cases, changes are needed at the level of software too.

In the linear economy, short product lifespans can be central to how companies generate revenue and longer product lifespans may therefore threaten overall sales volumes (Cooper 2012). This suggests that strategic shifts in business models and how value is created for producers and consumers is needed. Aligning businesses models with consumer preferences such as for product ownership can help increase uptake, while several forms of lifespan extension also require improvements in reverse logistics (Brooke Lyndhurst, 2013).

These changes are unlikely to come about on their own and effective policy and other ‘system enablers’ will be needed. A range of policy approaches can help extend the lifespans of products, components and materials. Ecodesign regulations including ‘right to repair’ standards were introduced in 2021 (HM Government, 2021) and can be extended to other products, for instance. Other policies to explore include improved consumer information and targeted changes in the tax system (Marcus et al. 2020). This series on lifespan extension will explore available strategies further to help establish key interventions which can leverage the potential benefits of longer product lifespans here in the UK.

**

If you’d like to discuss the ‘Extending Product Lifespans’ series further or find out about current projects and forthcoming outputs from the CE-Hub, please contact us at ce_hub@exeter.ac.uk.

Lead author: Oliver Lysaght.

With contributions from Peter Hopkinson, Markus Zils, Esmaeil Khedmati Morasae and Ryan Nolan.