Demystifying Series: Business and a circular economy

2022, CE-Hub Team

This paper is part of a series aimed at demystifying and providing context to a circular economy. The series is aimed at an audience of business people, policymakers and others who may already know something about circular economy, are interested in implementing it in their field of influence and wish to know more. This Demystifying series addresses the ‘what’ of circular economy, and the upcoming What Works series will address the ‘how’. We recommend reading the introductory ‘Demystifying a circular economy’ paper in advance of this one. A PDF version can be found at the end of this article, available to download and share.

Authors: Lucy Chamberlin & Georgie Hopkins

Reviewed by members of the Knowledge Hub Steering Group: Steve Evans, Simon Brown, Dan Dicker, Ali Moore, Isabelle Erixon, David Greenfield, Katie Lamb, Danielle Purkiss, Fiona Charnley.

Why is a circular economy important for business?

A circular economy can bring job creation, cost savings and increased resource productivity alongside environmental benefits, offering businesses as well as societies a way of operating within the limits of planetary resources and contributing to a sustainable economic system. The Ellen MacArthur Foundation for example has estimated that a shift to a circular economy could generate annual net benefits of €1.8 trillion across the EU by 2030[1], and in 2020 the EU made it one of the main building blocks of its European Green Deal, aimed at relieving pressure on natural resources and bringing sustainable growth and jobs[2]. A circular economy can also contribute to many of the UN Sustainable Development Goals[3].

Alongside ‘pull’ factors like these, changes in regulation and policy and public awareness are also increasing pressure on organisations to improve their environmental performance. And the stark reality of resource scarcity and rising raw materials prices can likewise push businesses to reassess their profit streams and revenue models[4].

How does value creation change for businesses in a circular economy?

It is becoming evident to businesses and governments that creating value for human society in the long term requires a new economic model that is less dependent on cheap, easily accessible materials and energy, and that is able to look after and restore ecosystems. Rather than merely capturing some value through recycling operations or second hand sales, when much value has already been lost, a circular economy aims to maintain and circulate products, components and materials at their highest value and for the longest time. This can be achieved in many ways, for example direct reuse, repair, remanufacture or refurbishment[5].

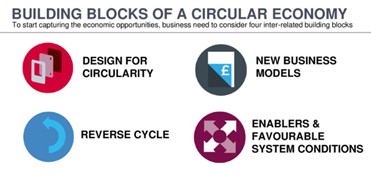

Companies may need to reconfigure their supply chains (e.g. with increased focus on reverse logistics), to collaborate with partners in new sectors or to redesign their product and service offerings. It may also alter their relationship with the customer, who might become more of a service user than a product consumer, and increasingly involved in return or subscription systems. Analysis of circular business case studies highlights four essential building blocks of circular business models[6]:

In order to create and realise value in a circular economy therefore, businesses can adopt different strategies. For example:

- They may maintain the product’s integrity at a high level, rather than taking it apart for refurbishment or recycling

- They may design for longevity in order to delay the need for additional purchases

- They may utilize products, materials or infrastructure in more than one value chain to save on costs of new materials, energy and labour

- They may use non-toxic feedstock from regenerative sources, to reduce the later costs of removing toxic particles from ecosystems

Design is another important strategy[7] that can help businesses to reframe their models, design out waste or develop substitutes (see also the Cradle to Cradle framework[8]). There are of course differences in the application of circular models[9], and as with all innovative business models the test of any value proposition is determined by the market. This throws up inevitable challenges around potential customer demand, first-mover advantage (or disadvantage) and how to account for the value of environmental and social benefits in a world that currently prioritises economic calculations over others.

Challenges and enablers of circular business models

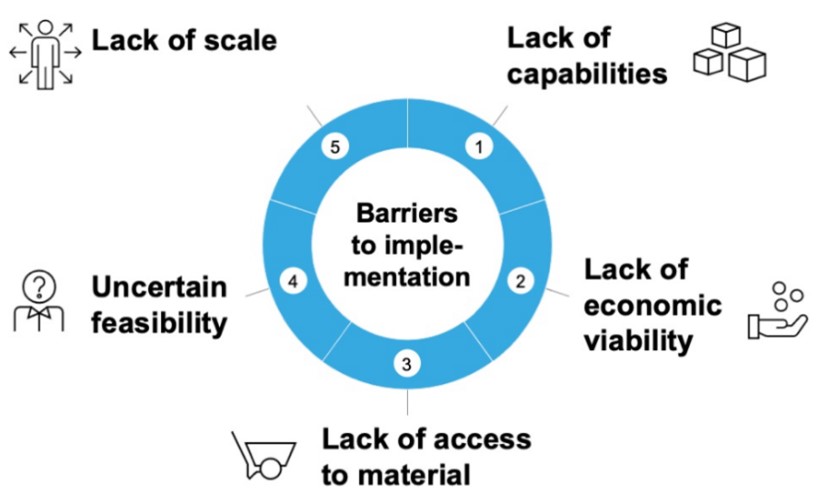

The concept of a circular economy is a complex one that can throw up some challenges when it comes to implementation[10]. Businesses and communities from different sectors (both public and private) need to work together[11], actors need to have the right skills, competences and know-how in order to unlock value from a circular economy, and ‘business as usual’ assumptions may need to change (for instance around product development and obsolescence, volume and source of materials, finance or profit models, and social and ecological outcomes). [12]

Design and technological development can be important enablers of circular business, for example new modular designs that facilitate repair or return, or digital tools that can quantify material stock compositions and connect secondary resources across markets[13]. Another critical enabler, particularly given the complexity of CE, is public policy that supports greater resource efficiency and use both regionally and across borders, with Government leadership and effective regulation both playing key roles. Infrastructure and reverse supply capabilities are also important, as are customer appetite or perception of new circular products and services. Finally, the management, values and operations of the organisation itself can prove vital in blocking or unlocking new opportunities for circular business.

Examples of circular businesses

Businesses have taken different approaches to implementing a circular economy:

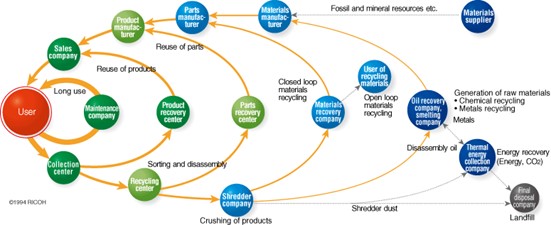

Ricoh

Established in 1984, Ricoh is the world’s leading manufacturer of photocopiers and printers and has developed a remanufacturing operation alongside the traditional sales route. This process has required a significant investment in systems and processes to ensure both operational efficiency and financial viability, but whilst the remanufacturing business demonstrates an effective circular business model, it is assessed by Ricoh entirely on an economical basis. To focus attention on the cycles of products, Ricoh developed the Comet Circle[14] almost thirty years ago, detailing company and third-party activity in terms of product lifecycles. Despite its age, this model bears many similarities to the material loops seen in more recently created diagrams of a circular economy.

Over the last decade Ricoh has also developed a leasing model of ‘selling a printed page’, rather than printing hardware, and this now represents around 50% of UK office automation revenue[15]. Two key challenges to overcome have been the long-term funding requirements of the model and the resource-heavy nature of maintaining and recovering assets at end of use. However, these are balanced by the benefit of maintaining control of the hardware, consumables and parts throughout the lifecycle. This final point is key given that the company has a policy of zero waste to landfill, which can be challenged by the linear sales model that transfers control of the assets to the customer, with no specified end-of-life plan. Essential to viability of the lease model proposition and ‘selling a printed page’, every component is monitored with tracking and use-meters providing appropriate granularity of detail to accurately assess the retained value in individual parts.

Oddbox Ltd

Based in London, Oddbox is a social impact business fighting food waste in UK farms. Around 30% of fresh fruit and vegetables produced in the UK is rejected by supermarkets for not meeting their specification, be that too bendy, too ugly, the wrong colour, too big or too small. The company works directly with farmers, taking excess seasonal stock and cutting out the supermarkets by offering direct home delivery to the end consumer[16]. From the farmers’ perspective, working with Oddbox provides both a fair price and safe disposal of food that would otherwise be left in the field or need to be disposed of. For customers, they receive the convenience of nutritious fruit and vegetables delivered to their home, at a price which is around 30% lower than similar subscription boxes[17], and with the added benefit of knowing that they are helping to alleviate food wastage. Additionally, Oddbox partner with two charities, donating any leftover produce at the end of each week and further minimising food waste. The shared value business model they have devised helps to build long-term partnerships between all actors through value distribution.

Since launching in 2016, they have delivered nearly 3 million boxes, saving over 19 tonnes of food waste, the equivalent of feeding almost 42,000 people for one year. Having started in London, the service has already expanded to include the South East and parts of the North of England. Through building a dedicated community, Oddbox has shown six-fold year on year growth since inception. Having raised £3m in March 2020, the company went on to secure a further £16m in Series B funding to further facilitate expansion plans across the UK[18].

Topolytics

As a data aggregation and analytics business, Topolytics is making the world’s waste visible, verifiable and valuable. The company collates and analyses multiple data sets from diverse sources to enable both waste producers and users to understand what material is where. Through data visualisation and interactive mapping, opportunities to harness the value in waste can be exploited, helping to improve both commercial and environmental outcomes. Additionally (and similar to other waste management technologies), research shows that through the process of recording waste outputs, increased awareness leads to a reduction in waste creation. In 2019, the company won a £500,000 contract to build the UK’s first digital waste tracking system, working alongside SAP and Google Cloud in this phase of development[19].

Swedish Return System

Tackling a different side of food production infrastructure, this business provides reusable pallets and storage crates for the transportation of food products, providing a solution to reduce emissions and packaging waste. With half of Sweden’s fresh produce deliveries to retailers now using the returnable crate system, the company contributed to reducing carbon emissions by almost 32,000 tonnes in 2019[20]. Conditions are advantageous for this innovative business given Sweden has an advanced deposit return system which has been in operation since 1984, reducing the adoption barrier which can often be a significant hurdle with new business models.

Useful resources

Tools to help to explore and facilitate businesses’ transition to a circular economy:

- Circular Business Model Design Guide: created by PA Consulting in collaboration with the University of Exeter and the Ellen MacArthur Foundation to help businesses to create, deliver and capture value from circular business models

- The Circular Design Guide: created by IDEO in collaboration with Ellen Macarthur Foundation

- Circular Advantage: a concise introduction to circular business models and why they are important, created by Accenture

- The Flourishing Enterprise Innovation Toolkit: a management innovation tool to enable leaders to design socially beneficial, environmentally regenerative and financially viable enterprises

- 30 ideas to kickstart CE in your business: a KTN tool to help businesses challenge the status quo and inspire new solutions to today’s problems.

- Design for demand: a circular economy resource for emerging designers in any industry or sector, developed by Forum for the Future

- Circulab: offers various tools to start the circular journey, including Circular Canvas, Partner Maps and Value Chain Canvas.

- Circularity Deck: a tangible card deck of circular economy strategies and principles, along with a simple and powerful framework to understand the circular economy.

References

[1] (EMF, 2015)

[2] https://ec.europa.eu/environment/strategy/circular-economy-action-plan_en

[3] (Shroeder et al, 2019)

[4] (Tura et al, 2019)

[5] https://www.resourcepanel.org/reports/re-defining-value-manufacturing-revolution

[6] Ellen MacArthur Foundation

[7] (Stumpf et al, 2021)

[8] (Braungart & McDonough, 2002)

[9] (Stumpf et al, 2021)

[10] (Jensen et al, 2021)

[11] (Stumpf et al, 2021)

[12] (Ludeke-Freund et al, 2019)

[13] (Tura et al, 2019; Shroeder et al, 2019)

[14] https://www.ricoh.com/sustainability/environment/management/concept

[15] Phil Hawkins, Ricoh UK Products Ltd, 2021, EMF Masterclass

[16] https://www.oddbox.co.uk/

[17] https://www.foodnavigator.com/Article/2018/10/01/OddBox-on-delivering-cheap-ethical-produce-and-combatting-food-waste

[18] https://www.uktech.news/news/london-based-sustainable-food-delivery-firm-oddbox-raises-16m-to-fight-food-waste-20210825

[19] https://topolytics.com/

[20] https://www.retursystem.se/en/

Demystifying Series: Business and a circular economy

Share this article in downloadable PDF form

Open PDF >>